Introduction to Star-Delta Starter

Most

induction motors are started directly on line, but when very large motors are

started that way, they cause a disturbance of voltage on the supply lines due

to large starting current surges. To limit the starting current surge, large induction motors are started

at reduced voltage and then have full supply voltage reconnected when they run

up to near rotated speed

A star delta

starter is the most commonly used method for the starting of a 3-phase

induction motor. In star delta starting an induction motor is connected in

through a star connection throughout the starting period. Then once the motor

reaches the required speed the motor is connected through delta connection.

Star Delta Consists Of

- Contactors (Main, star and delta contactors) 3 No’s (For Open State Starter) or 4 No’s (Close Transient Starter).

- Time relay (pull-in delayed) 1 No.

- Three-pole thermal overcurrent release 1 No.

- Fuse elements or automatic cut-outs for the main circuit 3 Nos.

- Fuse element or automatic cut-out for the control circuit 1No.

Working Mechanism

This is the

reduced voltage starting method. Voltage reduction during star-delta starting

is achieved by physically reconfiguring the motor windings as illustrated in

the figure below. During starting the motor windings are connected in star

configuration and this reduces the voltage across each winding 3. This also

reduces the torque by a factor of three.

After a

period of time the winding are reconfigured as delta and the motor runs

normally. Star/Delta starters are probably the most common reduced voltage

starters. They are used in an attempt to reduce the start current applied to

the motor during start as a means of reducing the disturbances and interference

on the electrical supply.

The

Star/Delta starter is manufactured from three contactors, a timer and a thermal

overload. The contactors are smaller than the single contactor used in a Direct

on Line starter as they are controlling winding currents only. The currents

through the winding are 1/root 3 (58%) of the current in the line.

There are

two contactors that are close during run, often referred to as the main

contractor and the delta contactor. These are AC3 rated at 58% of the current

rating of the motor. The third contactor is the star contactor and that only

carries star current while the motor is connected in star.

The current

in star is one third of the current in delta, so this contactor can be AC3

rated at one third (33%) of the motor rating.

Power Circuit

The main

circuit breaker serves as the main power supply switch that supplies

electricity to the power circuit.

The main

contactor connects the reference source voltage R, Y, B to

the primary terminal of the motor U1, V1, W1.

In

operation, the Main Contactor (KM3) and the Star Contactor (KM1) are closed

initially, and then after a period of time, the star contactor is opened, and

then the delta contactor (KM2) is closed. The control of the contactors is by

the timer (K1T) built into the starter. The Star and Delta are electrically

interlocked and preferably mechanically interlocked as well.

Star State: The Main [KM3] and the Star [KM1] contactors are closed and the delta [KM2] contactor is open. The motor is connected in star and will produce one third of DOL torque at one third of DOL current.

Open State: This type of operation is called open transition switching because there is an open state between the star state and the delta state. The Main contractor is closed and the Delta and Star contactors are open. There is voltage on one end of the motor windings, but the other end is open so no current can flow. The motor has a spinning rotor and behaves like a generator.

Delta State: The Main and the Delta contactors are closed. The Star contactor is open. The motor is connected to full line voltage and full power and torque are available

The star

contactor serves to initially short the secondary terminal of the motor U2, V2,

W2 for the start sequence during the initial run of the motor from standstill.

This provides one third of DOL current to the motor, thus reducing the high

inrush current inherent with large capacity motors at startup.

Controlling

the interchanging star connection and delta connection of an AC induction motor is

achieved by means of a star delta or wye delta control circuit. The control

circuit consists of push button switches, auxiliary contacts and a timer.

Control Circuit For Star Delta Starter

The ON push

button starts the circuit by initially energizing Star Contactor Coil (KM1) of

star circuit and Timer Coil (KT) circuit. When Star Contactor Coil (KM1)

energized, Star Main and Auxiliary contactor change its position from NO to NC.

When Star

Auxiliary Contactor (1) (which is placed on Main Contactor coil circuit )

become NO to NC it’s complete The Circuit of Main contactor Coil (KM3) so Main

Contactor Coil energized and Main Contactor’s Main and Auxiliary

Contactor Change its Position from NO to NC. This sequence happens in a

friction of time.

After pushing

the ON push button switch, the auxiliary contact of the main

contactor coil (2) which is connected in parallel across the ON push button

will become NO to NC, thereby providing a latch to hold the main contactor coil

activated which eventually maintains the control circuit active even after

releasing the ON push button switch.

When Star

Main Contactor (KM1) close its connect Motor connects on STAR and it’s

connected in STAR until Time Delay Auxiliary contact KT (3) become NC to NO.

Once the

time delay is reached its specified Time, the timer’s auxiliary contacts

(KT)(3) in Star Coil circuit will change its position from NC to NO and at the

Same Time Auxiliary contactor (KT) in Delta Coil Circuit(4) change its

Position from NO To NC so Delta coil energized and Delta Main Contactor

becomes NO To NC. Now Motor terminal connection change from star to delta

connection.

A normally

close auxiliary contact from both star and delta contactors (5&6)are also

placed opposite of both star and delta contactor coils, these interlock

contacts serves as safety switches to prevent simultaneous activation of both

star and delta contactor coils, so that one cannot be activated without the

other deactivated first. Thus, the delta contactor coil cannot be active when

the star contactor coil is active, and similarly, the star contactor coil

cannot also be active while the delta contactor coil is active.

The control

circuit above also provides two interrupting contacts to shutdown the motor.

The OFF push button switch break the control circuit and the

motor when necessary. The thermal overload contact is a protective device which

automatically opens the STOP Control circuit in case when motor

overload current is detected by the thermal overload relay, this is to prevent

burning of the motor in case of excessive load beyond the rated capacity of the

motor is detected by the thermal overload relay.

At some

point during starting it is necessary to change from a star connected winding

to a delta connected winding. Power and control circuits can be arranged to

this in one of two ways – open transition or closed transition.

Open Transition Starter

Discuss

mention above is called open transition switching because there is an open

state between the star state and the delta state.

In open

transition the power is disconnected from the motor while the winding are

reconfigured via external switching.

When a motor

is driven by the supply, either at full speed or at part speed, there is a

rotating magnetic field in the stator. This field is rotating at line frequency.

The flux from the stator field induces a current in the rotor and this in turn

results in a rotor magnetic field.

When the

motor is disconnected from the supply (open transition) there is a spinning

rotor within the stator and the rotor has a magnetic field. Due to the low

impedance of the rotor circuit, the time constant is quite long and the action

of the spinning rotor field within the stator is that of a generator which

generates voltage at a frequency determined by the speed of the rotor.

Note:

When the motor

is reconnected to the supply, it is reclosing onto an unsynchronized generator

and this result in a very high current and torque transient. The

magnitude of the transient is dependent on the phase relationship between the

generated voltage and the line voltage at the point of closure can be much

higher than DOL current and torque and can result in electrical and mechanical

damage.

Open

transition starting is the easiest to implement in terms or cost and circuitry

and if the timing of the changeover is good, this method can work well. In

practice though it is difficult to set the necessary timing to operate

correctly and disconnection/reconnection of the supply can cause significant

voltage/current transients.

Four states of open transition

OFF State: All Contactors are open.

Star State: The Main [KM3] and the Star [KM1] contactors are closed and the delta [KM2] contactor is open. The motor is connected in star and will produce one third of DOL torque at one third of DOL current.

Open State: This type of operation is called open transition switching because there is an open state between the star state and the delta state. The Main contractor is closed and the Delta and Star contactors are open. There is voltage on one end of the motor windings, but the other end is open so no current can flow. The motor has a spinning rotor and behaves like a generator.

Delta State: The Main and the Delta contactors are closed. The Star contactor is open. The motor is connected to full line voltage and full power and torque are available

Closed Transition Star-Delta Starter

There is a

technique to reduce the magnitude of the switching transients. This requires

the use of a fourth contactor and a set of three resistors. The resistors must

be sized such that considerable current is able to flow in the motor windings

while they are in circuit.

The

auxiliary contactor and resistors are connected across the delta contactor. In

operation, just before the star contactor opens, the auxiliary contactor closes

resulting in current flow via the resistors into the star connection. Once the

star contactor opens, current is able to flow round through the motor windings

to the supply via the resistors. These resistors are then shorted by the delta

contactor.

If the

resistance of the resistors is too high, they will not swamp the voltage

generated by the motor and will serve no purpose.

This is

achieved by introducing resistors to take up the current flow during the

winding changeover. A fourth contractor is required to place the resistor in circuit

before opening the star contactor and then removing the resistors once the

delta contactor is closed.

These

resistors need to be sized to carry the motor current. In addition to requiring

more switching devices, the control circuit is more complicated due to the need

to carry out resistor switching.

Five states of closed transition

OFF

State. All

Contactors are open

Star

State. The Main

[KM3] and the Star [KM1] contactors are closed and the delta [KM2] contactor is

open. The motor is connected in star and will produce one third of DOL torque

at one third of DOL current.

Star

Transition State. The

motor is connected in star and the resistors are connected across the delta

contactor via the aux [KM4] contactor.

Closed

Transition State. The

Main [KM3] contactor is closed and the Delta [KM2] and Star [KM1] contactors

are open. Current flows through the motor windings and the transition resistors

via KM4.

Delta

State. The Main

and the Delta contactors are closed. The transition resistors are shorted out.

The Star contactor is open. The motor is connected to full line voltage and

full power and torque are available.

Reason Behind Using Star Delta

We use star

delta which, is also called wye delta in north America, to reduce the inrush current

when the motor starts. When large induction motors start in delta their

starting current can be over 5 times higher than the full load current which

occurs when the motor stabilises and runs normally.

This huge

surge in current can cause lots of problems. The buildings electrical system

will be hit by this sudden large demand. The electrical infrastructure will

rapidly increase in temperature leading to component failure and even

electrical fires. The sudden demand also causes voltage drops throughout the

buildings electrical system which we can visually see because the lights will

dip, this can cause many problems for things such as computers and servers.

So to reduce

the starting current we simply need to reduce the starting voltage.

The star

configuration will reduce the coil voltage to around 58% compared to the delta

configuration. A lower voltage will lead to a lower current. The current in the

coil while in star configuration will be around ~33% of the delta

configuration. This will also lead to a reduction in torque, the star

configuration torque will also be around 33% compared to delta.

Inside Operation With Basic Example

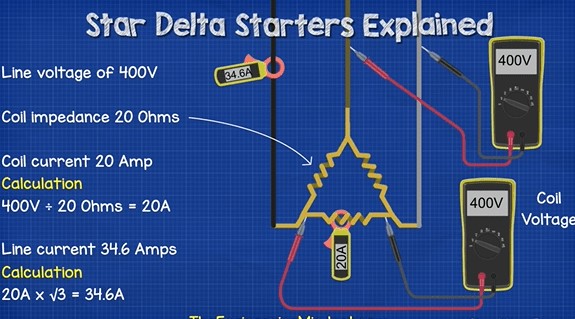

Let consider

we have the motor connected in delta with supply voltage of 400V.

If we measure across the two ends of a coil, we again measure the line to line voltage of 400V. Let say each coil has a resistance, or impedance as this is AC power, of 20 Ohms. That means we will get a current reading on the coil of 20 Amp. We can calculate that from 400V / 20 Ohms = 20A. But the current in the line will be different, it will be 34.6A and we get that from 20A x sqr3 = 34.6A

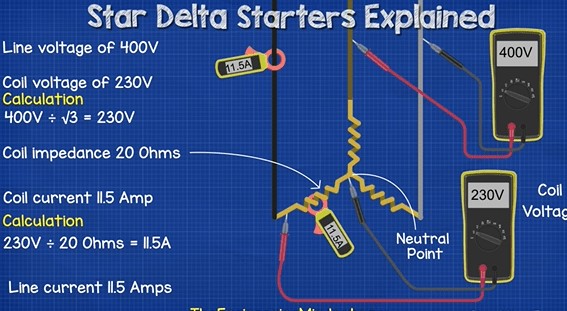

If we then

looked at a star connection. We again have a line to line voltage of 400V, if

we measure between any two phases. But, with the star connection all our coils

meet at the star point or neutral point. We can run a neutral line from this

point. So When we measure the voltage across the ends of the coil, we get a

lower value of 230V, that’s because the coil isn’t directly connected between

two phases like the delta version. One end is connected to a phase, the other

end is connected to a shared point, so the voltage is therefore shared and will

be less because one of the phases is always is reverse.

We can see

the 230V reading by dividing the 400V by sqr3 = 230V. As the voltage is less

the current will be too. If the coil is again 20ohms of resistance, or

impedance, then the current is calculated by 230V / 20ohms which is 11.5Amp.

The current in the line will also be 11.5A.

So with the

delta connection the coil is exposed to the full 400V between two phases. But

the star connection is only exposed to 230V between the phase and neutral. So

we can see that the star uses less voltage and therefore less current compared

to the delta version, which is why we use it first.

Features

- For low- to high-power three-phase motors.

- Reduced starting current

- Six connection cables

- Reduced starting torque

- Current peak on changeover from star to delta

- Mechanical load on changeover from star to delta

Advantages

- The operation of the star-delta method is simple and rugged

- It is relatively cheap compared to other reduced voltage methods.

- Good Torque/Current Performance.

- It draws 2 times starting current of the full load ampere of the motor connected

No comments:

Post a Comment